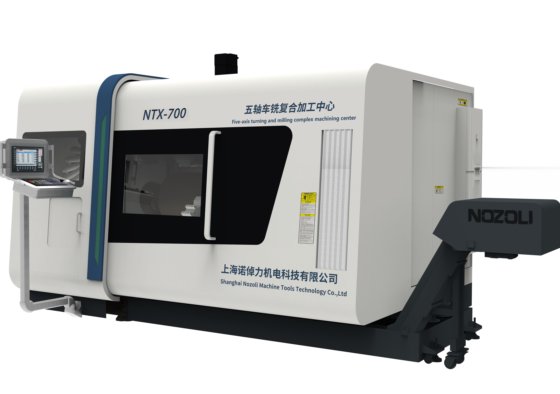

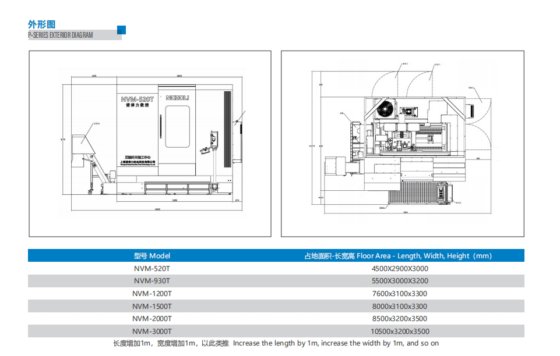

新 车铣复合五轴加工中心 在 上海市, 中国

新

Doubleclick to zoom in

请联系卖家咨询

更多照片和设备细节。

描述

床身、工作台、立柱横梁、滑枕、滑架均采用度铸铁材料,经二次时效处理,机床抗震性能强。

满足机床重负荷切削,立柱、横梁内部交叉筋布置,极大提高了机床的精度稳定性。

三轴结构对称设计,保证运行稳定性和极高的热稳定性 Z 轴采用平衡油缸配重,使 Z 轴运行更加稳定顺畅。

可将汽车框架件检具公差控制在 0.02mm 以内。

滚柱直线导轨和丝杠均配置自动集中润滑系统,使用成本低且高效环保。

龙门大跨距,给客户提供宽阔的加工空间。

The bed, workbench, column beam, ram and carriage are all made of high-quality and high-strength cast iron materials, which have

been treated by secondary aging, and the machine tool has strong seismic performance.

To meet the heavy-duty cutting of the machine tool, the internal cross rib arrangement of the column and beam greatly improves

the accuracy and stability of the machine tool.

The best symmetrical design of the three-axis structure ensures the running stability and extremely high thermal stability, and the

Z-axis adopts the counterweight of the balance cylinder, which makes the Z-axis run more stable and smooth.

The tolerance of the inspection tool of the automobile frame part can be controlled within 0.02mm.