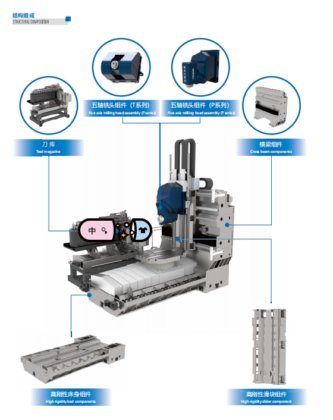

新 卧式五轴加工中心(T系列) 在 上海市, 中国

新

Doubleclick to zoom in

请联系卖家咨询

更多照片和设备细节。

描述

五轴卧式加工中心采用先进的平台化开发设计理念。

平台主机结构均采用L型墙式结构,左右动大滑板结构实现X轴进给运动。

上下动主轴实现Z轴运动。

前后动工作台实现Y轴进给运动。

主轴基础件采用热对称结构设计,应用有限元分析优化,基础件具有高精度、高刚性,高稳定性等特点。

特殊的床身结构设计,保证足够的排屑角度,圈平台系列产品实现整体后排屑。

全系列产品标配ATC自动换刀装置,可选大容量刀库系统,满足多工序、多特征的加工需求。

The five axis horizontal machining center adopts advanced platform based development and design concepts.

The platform host structure adopts an L-shaped wall structure, and the left and right large sliding plate structure achieves X-axis feed motion.

Move the spindle up and down to achieve Z-axis movement.

The front and rear moving worktable achieves Y-axis feed motion.

The spindle foundation is designed with a thermal symmetric structure and optimized using finite element analysis. The foundation has the

characteristics of high precision, high rigidity, and high stability.

The special bed structure design ensures sufficient chip removal angle, and the circular platform series products achieve overall chip removal.